RITE TRACK

Coat Develop Scrub

Photoresist Coat & Develop Systems to Suit Any Need

- COAT

- DEVELOP

- SCRUB

The Industry's Best Production Systems

Fully refurbished for value and performance

- TEL ACT 8/12

- TEL MARK 8

- TEL MARK 7

- TEL MARK Vz

- SVG 90-S/SE

- SVG 88

- SVG 86

- DNS 80

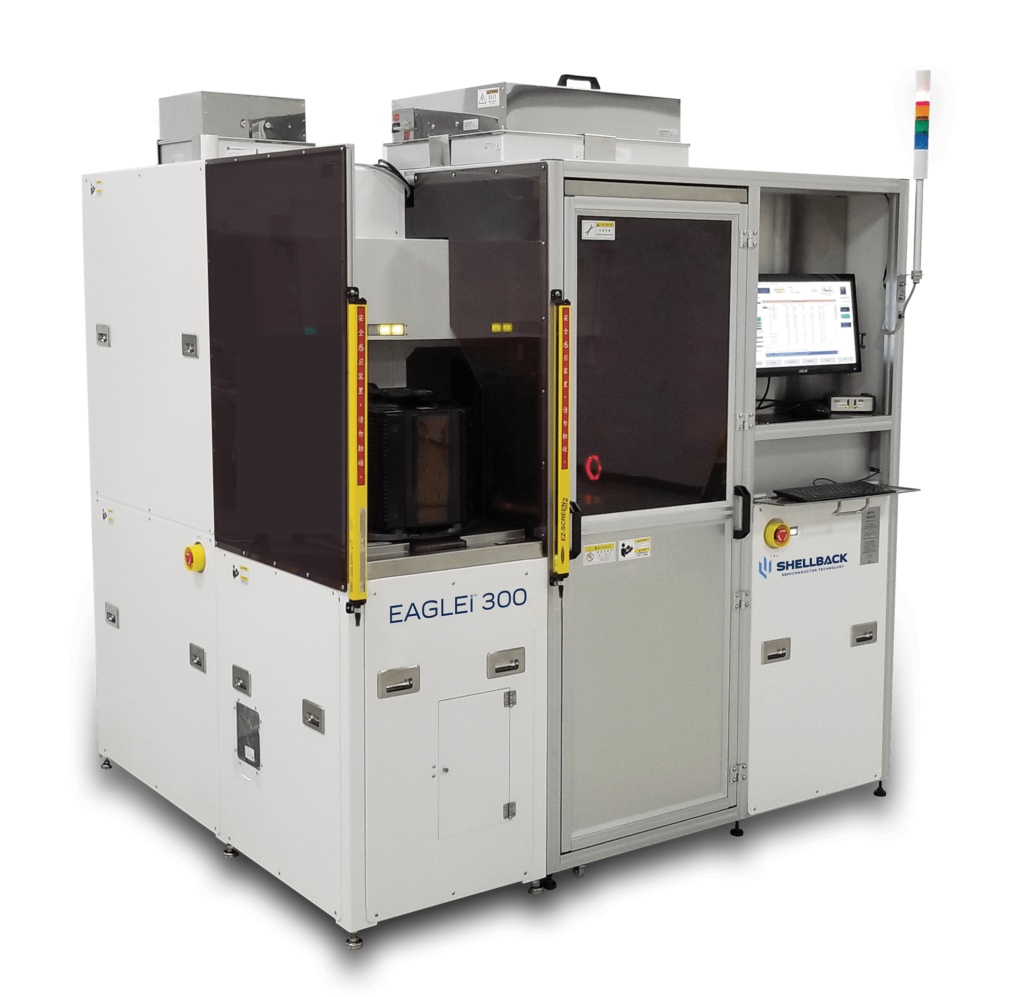

TEL ACT 8 . TEL ACT 12

- Refurbished, full warranty

- Industry expert

The TEL ACT 8/12 is world-renowned for reliability & performance. Designed for high-volume production, the ACT 8/12 provides a fab friendly footprint with 7-Tier thermal units and stacked spin modules. It is capable of volume 100-200 mm & 300mm wafer production.

- ACT 8: 100-200 mm wafers / ACT 12: 200-300mm wafers

- Stacked coaters and developers

- Seven-high stacked thermal modules

- Proven reliability and process stability for I-Line, 248nm and 193nm processes.

- GEM or SECS capable

TEL MARK 7 . TEL MARK 8

- Refurbished, full warranty

- Industry expert

The MARK 7/8 is an industry-favorite photoresist coat-develop system with a vast install base capable of processing 100 to 200 mm Si, GaAs, Glass and Ceramic Wafers among others. Designed to meet the demands of high volume, high throughput manufacturing for sub-micron geometries, the MARK 7/8 triple arm transfer increases throughput over competing systems. Four tier stacked hot plates reduce system footprint while enhancing process control.

- 100-200 mm Substrates

- Random-Path Wafer Flows

- Single Wafer/Lot Control

- Four Tier Stacked Thermal Modules

- Vacuumless Triple Arm Transfer

- SECS I/II, GEM Compliant

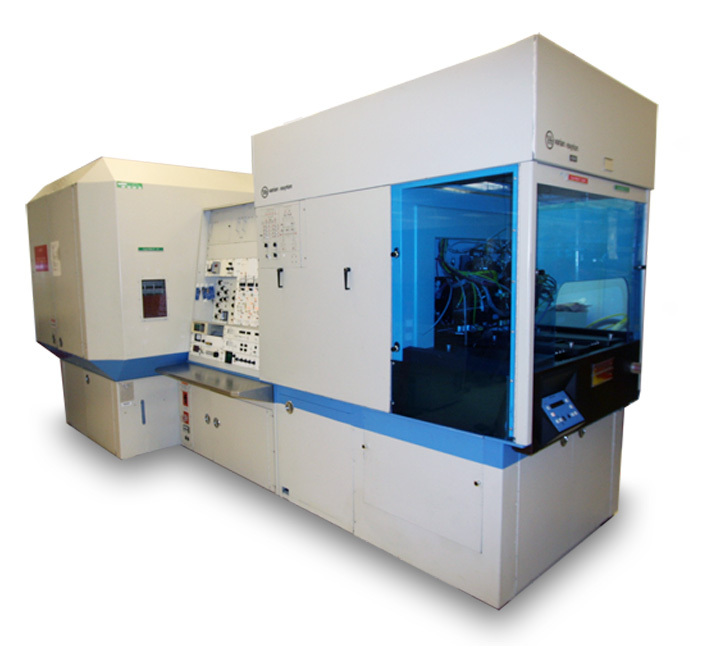

SVG 90-S / SE

- Refurbished, full warranty

- Product line owner

Designed to meet the requirements of advanced photoresist process applications, from leading-edge manufacturing fabs, the 90-S/S offers 100mm – 200mm enhanced substrate handling with stacked thermal modules. Submicron processing (down to 0.18um) capabilities plus process and contamination control features make the 9X series ideal for submicron manufacturing environments in DUV or I-line settings.

A key automation feature is the MultiPath™ substrate transfer system, maximizing throughput by combining serial and random transfer modes while eliminating bottle necks caused by lengthy process steps. MultiPath also eliminates process control problems by ensuring that serial arms are present for substrate transfer between critical process steps such as post-exposure bake to chill.

- 100-200mm Substrates

- Random-Path Wafer Flows

- MultiPath™ substrate transfer system

- Single Wafer/Lot Control

- Two Tier Stacked Thermal Modules

TEL MARK VZ

- Refurbished, full warranty

- Industry expert

- 3″-150 mm Substrates

- Random-Path Wafer Flows

- Vacuumless Twin Arm Transfer

- Two Tier Stacked Thermal Modules

- Up to 120 wph

- Single Wafer/Lot Control

SVG 88

- New or refurbished, full warranty

- Product line owner

The fully featured 88 Series is ideal for submicron manufacturing. All 88 series systems are capable of processing 3″ through 150 mm substrates. Silicon, GaAs, Sapphire, GGG, Lithium Niobate, thin film heads, MEMS and many other substrate types are routinely processed on 88 Series systems. Rite Track is the exclusive owner of the SVG 88 series product line (acquired in 2003) including the SVG 88 Coater, Developer, and Scrubber.

The 88 series uses an enhanced in-line robotic transfer arm between each module. Critical transfers, such as between soft bake and chill, are much more easily controlled compared to a totally random robotic system.

- 3″-150 mm Substrates

- Square or Round Substrates

- Gentle, Belted Transfer

- Single Wafer/Lot Control

- SECS or GEM Host Communication with optional NetTRACK System Manager

- 99 Recipe Capability with NetTRACK Option

SVG 86

- New or refurbished, full warranty

- Product line owner

- 2″-150 mm Substrates

- Square or Round Substrates

- Gentle, Belted Transfer

- Single Wafer/Lot Control

- SECS or GEM Host Communication with optional NetTRACK System Manager

- 99 Recipe Capability with NetTRACK Option

Scrubber systems

Scrubber systems

- Refurbished, full warranty

- Industry expert

Shellback can provide a variety of scrubber systems based on your needs and budget. Scrub version include ultrasonic, hi pressure spray and/or brush scrub. See models listed below.

- DNS SS-80B Scrubber with Nanospray Option

- TEL Mark 7/8 Jet Scrub

- SVG 86 and 88 Scrubber

- DNS 80B Coat & Develop Systems also available